Introducing the Laserhawk LH5, a state-of-the-art Laser Engraving Machine that redefines precision and versatility in the world of laser cutting and engraving. Whether you’re a hobbyist or a professional, the Laserhawk LH5 is designed to meet your creative and industrial needs with unmatched performance.

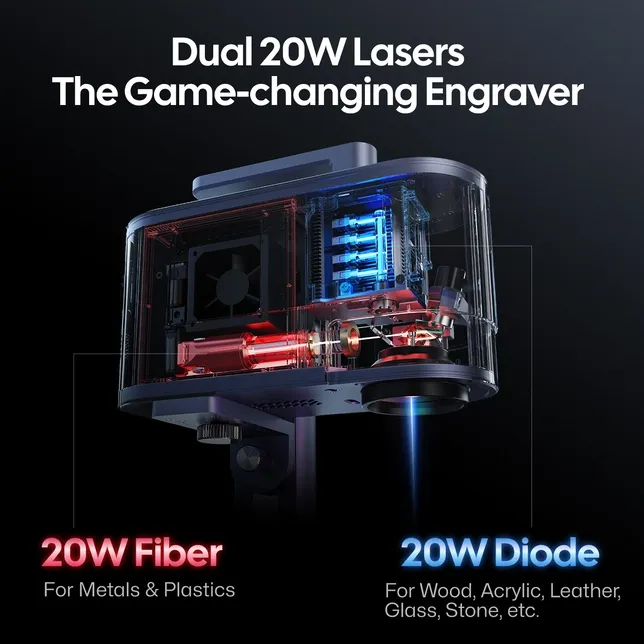

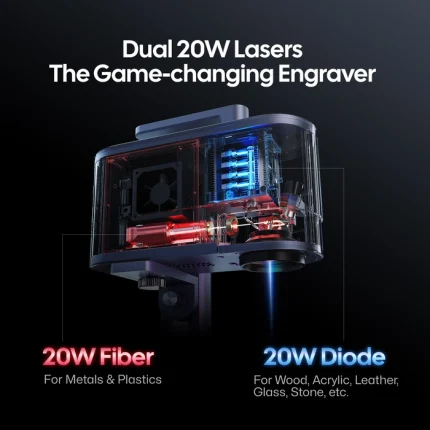

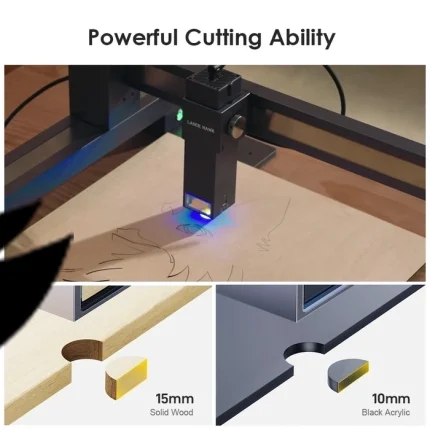

This Diode Laser Engraver is equipped with advanced features that make it stand out from the competition. With its powerful laser module, the Laserhawk LH5 can effortlessly engrave on a variety of materials, including wood, acrylic, leather, and even laser engraving on metal. Its high precision and speed ensure that every detail of your design is captured perfectly.

- Versatile Engraving Capabilities: From intricate laser engraving lamp designs free download to detailed laser engraving LightBurn STL grayscale images, the Laserhawk LH5 handles it all with ease.

- User-Friendly Interface: The intuitive control panel and compatibility with popular design software make it easy for users of all skill levels to operate.

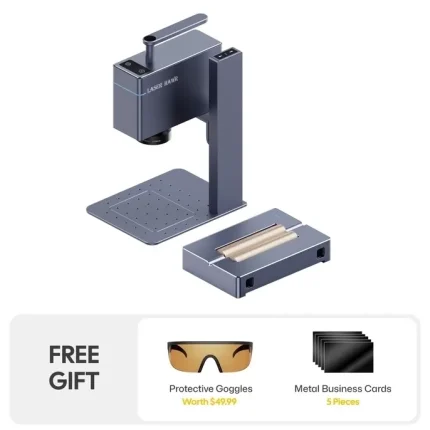

- Compact and Portable: Despite its powerful capabilities, the Laserhawk LH5 is designed to be compact and portable, making it ideal for both home and professional workshops.

- Safety Features: Equipped with advanced safety mechanisms, including emergency stop and protective eyewear, ensuring a safe working environment.

Whether you’re creating custom gifts, personalized items, or industrial prototypes, the Laserhawk LH5 is your ultimate tool for bringing your ideas to life. Its ability to handle laser engraving on metal and other challenging materials sets it apart, making it a must-have for any serious engraver.

Explore the endless possibilities with the Laserhawk LH5 and take your creative projects to the next level. With its robust build, cutting-edge technology, and user-friendly design, this Laser Engraving Machine is the perfect addition to your workshop.

More you like:

Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series

Jessica Li –

Five stars for this laser engraver! The engraving effects are crisp & precise. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Lucia Sato (verified owner) –

**Laser Engraver Experience as an Architectural Model Maker**

1. **Specific Project Experience:**

– **Project Overview:** Utilized a laser engraver for creating intricate textures on wooden surfaces in an architectural model of a historic building. The goal was to replicate detailed stone patterns and wood grain effects.

– **Material Behavior:** Wood reacted well under the laser, allowing precise control over depth. However, high power settings caused charring, which required adjustments.

– **Challenges & Solutions:** Encountered uneven engraving due to varying wood density. Adjusted power settings dynamically and used masking techniques to achieve consistent results.

2. **Technical Performance:**

– **Power Settings:** Different woods required varied power levels; oak needed higher settings than plywood to ensure deep, crisp engravings.

– **Precision:** The laser’s precision enabled the creation of fine details, essential for scale models, such as delicate patterns and textures.

– **Software Features:** Used bitmap engraving for complex designs and layering for multi-color effects. Air assist significantly reduced charring, enhancing finish quality.

3. **Business/Creative Impact:**

– **Workflow Improvement:** Laser engraving cut production time by 50% compared to manual methods, allowing more efficient model creation.

– **Material Efficiency:** Reduced waste as precise cuts minimized errors and material usage.

– **Creative Freedom:** Enhanced ability to incorporate complex designs, leading to more professional and detailed models.

– **Customer Feedback:** Clients appreciated the increased professionalism and detail, resulting in repeat business and referrals.

4. **Comparison & Value:**

– **Cost-Effectiveness:** Laser engraving proved cheaper than hiring craftsmen for intricate details and faster than CNC routers for certain tasks.

– **Time Savings:** Allowed taking on more projects or enhancing each model’s quality due to time efficiency.

– **Return on Investment:** The tool quickly paid for itself through increased productivity and client satisfaction, justifying its cost.

This approach highlights the laser engraver’s role in streamlining operations, enhancing creativity, and contributing to business growth.

Ming Chen –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”